Have you ever wondered how those massive aluminum tools and engine parts are made? They were most emphatically not made by hand or in a furnace. These pieces are created using a method known as CNC precision machining.

CNC precision machining is a production procedure that uses computer programs to make any product to exact specifications for individuals who are new to the manufacturing sector. This page will outline the method, the many pieces of equipment utilized, their applications, as well as the various programming and processing involved. If you want to understand more about this manufacturing method, keep reading till the end.

What Is CNC Precision Machining?

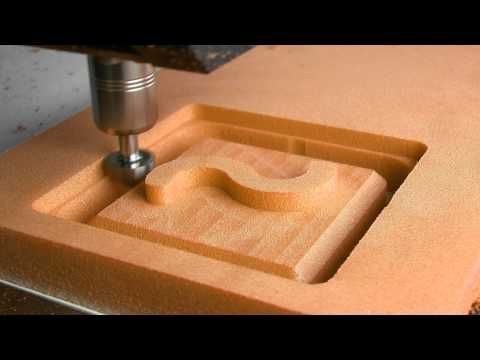

If you’re still wondering, “What is precision machining?” here’s your answer. CNC Precision machining, as the name indicates, is an abbreviation for Computer Numerical Control Precision Machining entails molding raw material into a completed product by cutting off excesses as specified by a Computer-Aided Design (CAD) or Computer-Aided Manufacturing (CAM) plan. Machinists employ this procedure in a variety of industrial processes and materials.

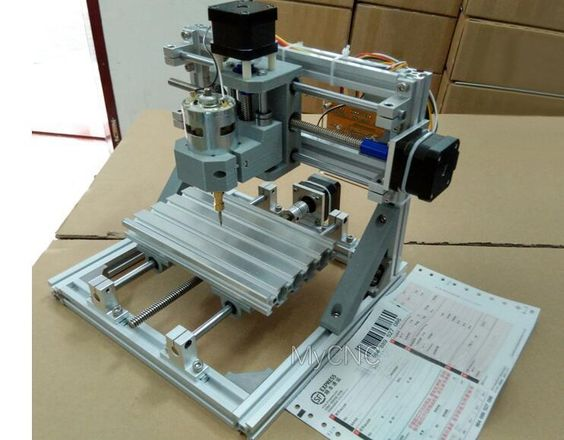

CNC machines are available in a variety of configurations and levels of sophistication. Some machines can hold many tools at once and work along the X, Y, and Z axes to remove superfluous material from any side or angle.

History Of CNC Machine

The earliest CNC machines were created in the 1940s and 1950s, and they used a standard telecommunication data storage method called “punched tape” or “perforated paper tape.” Punched tape technology has long been outdated since the data medium soon shifted to analog and subsequently digital computer processing in the 1950s and 1960s. CNC machines continue to increase their efficiency as new technologies and greater digital processing capability are developed.

Top-of-the-Line Machining Technology

In general, machining is a process that uses a controlled material removal procedure to change a stock piece of material, such as a block of plastic, into a completed product (usually a prototype item). CNC, like another prototyping method, FDM (3D printing), is based on digital instructions from a Computer-Aided Manufacturing (CAM) or Computer-Aided Design (CAD) file, such as Solidworks 3D. While the CAM or CAD does not operate the CNC machine, it does give a roadmap for the CNC to follow to produce the designs. The design is interpreted by the CNC machine into instructions for cutting prototype pieces.

CNC machining equipment is cutting-edge. People operating levers, touching things excessively, and pushing buttons are a thing of the past. Regardless of the type of CNC machine utilized, the computer components are now the “live operator,” moving the cutting tools and shaping the material, which might be metal, plastic, wood, glass, foam, composite, or something else.

Astonishing Range of Applications

The versatility of CNC machining with a wide range of materials (aluminum, gray iron, ductile iron, austempered ductile iron, steel, stainless steel, brass, bronze, and others) may help firms of all sizes compete when designing unique components and designs. Furthermore, very accurate tolerances may be obtained consistently, generating consumer confidence.

Metalworking, automotive, aerospace, agricultural, construction, power generation, maritime, transportation, recreation and consumer products, military/defense, industrial equipment, and other industries may profit. Furthermore, the types of CNC machines vary as much as the industries they serve.

Improved Tool Performance and Reliability

While standard machining is enough for certain sectors, others demand tolerances as fine as +/-.0005. This kind of precision necessitates CNC accuracy. Furthermore, tens of thousands of identical components are sometimes required, which is unachievable without CNC’s reproducibility.

When the production part approval process (PPAP) is finished, everything is in place to generate repeat orders regularly. With the right hydraulic valve supplier, CNC machines make more accurate dimensions and irregular shape designs precisely. The fixture has been constructed. The tooling is ready, and the programs have been tested. Quality assurance procedures are in place. Now, the machine makes the same cut while maintaining the same excellent quality.

Reduced Cycle Times And Labor Costs

CNC’s improved production manufacturing automation, as well as the ability to program without interrupting machine use, enable larger production needs to be met with less dependence on the machinist or operator. CNC machines are designed for optimum precision and reproducibility, whether they are manufacturing a hundred or thousands of machined components.

Conventional machining necessitates the use of a machinist to program the machine as well as monitor and optimize ideal running speeds and tooling. CNC machines run offline-created software. A setup operator frequently converts a machining center to create a different item by loading the new program, changing fixtures and tools, and cutting the initial pieces to validate the process. A machine operator frequently takes over and runs production from here.

Quality

When it comes to excellent quality, CNC is unrivaled. Variations in traditional machining are eliminated when utilizing a numerically controlled machine. It can run continuously for 24 hours with minor preventative maintenance, and modern software makes it (relatively) simple to fulfill design specification modifications on complicated parts. Furthermore, comprehensive testing of a complicated CNC item ensures that high-quality machining and innovative technologies are employed to surpass client expectations.

Conclusion

CNC precision machining is undoubtedly the most efficient method of producing custom-made items. Aside from saving you money, it takes very little time and leaves minimal room for error. Incorporate this manufacturing method into your operations now!

Follow Techdee for more informative articles.